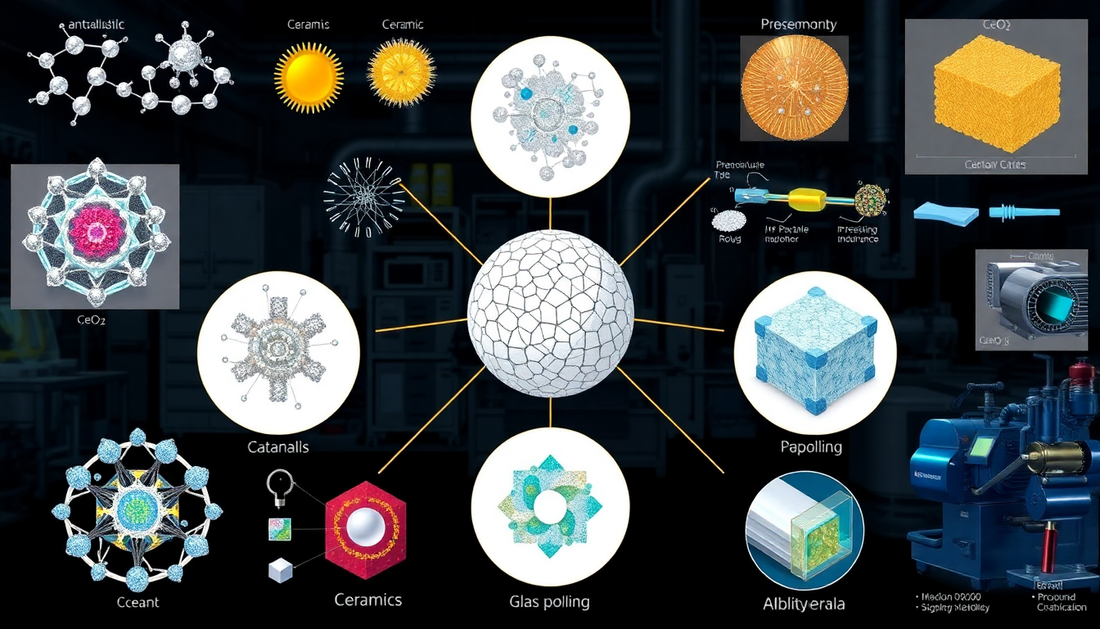

The versatile applications of cerium oxide in industry and technology

Cerium oxide, also known as cerium dioxide or CeO2, is an important mineral used in a variety of industrial and technical applications. As one of the rare earth elements, cerium oxide has unique properties that make it a valuable raw material. In this blog post, we want to take a closer look at the various applications of cerium oxide.

Glass polishing and surface finishing

One of the best-known applications of cerium oxide is glass polishing. Due to its high hardness and abrasiveness, cerium oxide is excellent for removing scratches and unevenness on glass surfaces. In the glass industry, cerium oxide powder is therefore often used as a polishing agent to achieve a perfectly smooth and shiny surface.

In addition to glass, cerium oxide can also be used to polish and refine other materials such as metals, ceramics, or plastics. The use of cerium oxide-containing polishing pastes and suspensions makes it possible to achieve a high-quality surface finish, which is particularly important in the automotive industry, electronics manufacturing, and jewelry making.

Cerium oxide polishing for crystal-clear surfaces

The use of cerium oxide as a polishing agent is based on its high hardness and abrasiveness. With the help of cerium oxide particles, even stubborn scratches and unevenness can be effectively removed without damaging the surface. It is not only the correct grain size of the cerium oxide powder that matters but also the composition and consistency of the polishing agent.

High-quality cerium oxide polishing pastes and suspensions are formulated to enable optimal smoothing and polishing of surfaces without attacking or scratching them. By using state-of-the-art technologies, cerium oxide-based polishing agents today can achieve a surface quality that meets even the highest demands.

Catalysts and fuel cells

In addition to surface finishing, cerium oxide also finds diverse applications in catalyst technology. As a catalyst component, cerium oxide plays an important role in reducing pollutants in exhaust gases from combustion engines. Due to its ability to store and release oxygen, cerium oxide supports the oxidation process and thus improves the efficiency of catalysts.

Furthermore, cerium oxide is also used in fuel cells. Here it serves as an electrolyte material that enables the transport of oxygen ions, thereby increasing the efficiency of the cell. Cerium oxide-based fuel cells are characterized by high performance and durability, making them a promising technology for future energy supply.

Cerium oxide as a key component in catalyst technology

The ability of cerium oxide to reversibly store and release oxygen makes it a valuable component of catalysts. In exhaust gas catalysts of combustion engines, cerium oxide supports the oxidation process by absorbing oxygen when there is an excess and releasing it again when there is a lack of oxygen.

In this way, cerium oxide helps to effectively reduce pollutant emissions from vehicles. Modern three-way catalysts use the oxygen storage capacity of cerium oxide to convert carbon monoxide, hydrocarbons, and nitrogen oxides into harmless substances.

Ceramic materials and refractory materials

In addition to the applications already mentioned, cerium oxide is also used in ceramics manufacturing and refractory materials. As a high-temperature resistant material, cerium oxide is excellently suited for use in high-temperature applications such as melting furnaces, combustion chambers, or heat protection linings.

Cerium oxide-containing ceramics are characterized by their high hardness, wear resistance, and chemical stability. They are therefore used in a variety of industrial sectors, from steel and glass production to aerospace technology.

Cerium oxide ceramics for extreme conditions

Cerium oxide-based ceramics are predestined for use under extreme conditions due to their excellent material properties. Their high temperature resistance, corrosion resistance, and mechanical stability make them ideal materials for use in high-temperature processes.

In the steel and glass industries, cerium oxide ceramics are used, for example, as linings for melting furnaces, where they must withstand high temperatures, wear, and aggressive chemicals. Cerium oxide ceramics are also used in aerospace technology for heat protection coatings to protect spacecraft from the extreme conditions during re-entry into the atmosphere.

Further applications of cerium oxide

In addition to the main application areas mentioned, cerium oxide is also used in a number of other industries and technologies:

- Polishing and grinding agents: Cerium oxide powder is used in polishing pastes and suspensions for surface finishing of glass, metals, plastics, and ceramics.

- Ceramic pigments: Cerium oxide serves as a colorant for ceramic glazes and enamel, enabling intense yellow to orange hues.

- Electronic components: In the electronics industry, cerium oxide is used as a dielectric in capacitors or as a semiconductor material.

- Medical applications: Due to its biocompatibility, cerium oxide is used in medical technology for implants, prostheses, and dental fillings.

- Cosmetics and personal care: Cerium oxide is found in sunscreens, makeup, and other cosmetic products as UV protection and color pigment.

The versatility of cerium oxide is demonstrated by the wide range of applications this rare earth element offers. From surface finishing to catalyst technology to high-temperature resistant ceramics - cerium oxide is an indispensable raw material for numerous industries and technologies.

Conclusion

Cerium oxide is a fascinating mineral with a variety of useful properties. Whether as a polishing agent, catalyst component, or material for high-temperature applications - cerium oxide is used in many areas of industry and technology.

The unique properties of cerium oxide, such as its oxygen storage, temperature resistance, and abrasiveness, make it a valuable raw material that enables the development of innovative products and technologies. With the increasing demand for powerful and environmentally friendly solutions, the importance of cerium oxide will continue to grow in the future.